Thermal Spray Process (Technical Collaboration)

We wish to introduce ourselves as one of the leading Engineering & Metalizing service provider company in India having complete range of advance Metal Coating Systems.

We offer solution to overcome problems of Wear, Corrosion, Erosion, Abrasion and Thermal Conductive / Insulation. We also carry out Reclamation / Reconditioning of worn out parts / jobs by cold metalizing with complete Machining, Grinding & Super Finishing as per required size. With the use of Metalizing Process no mechanical and metallurgical deformation will overcome on the job.

Send Enquiry

Send Enquiry

Our organization is focused towards life enhancement of industrial components through surface modifications. We provide thermal spraying services to Steel, Power, and Paper, Printing, Textile, Chemical, Fertilizer and Petrochemical industries.

Following are our areas of core competency:

- Reclamation and Metal spray coating on Reactors, Vessels, Tanks, Valves & Critical machinery components.

- Manufacturing of precision parts and components with metals and ceramic spray coatings (As per customer’s drawing and specifications).

- Hard chrome plating, Grinding, Super and mirror polishing on industrial component.

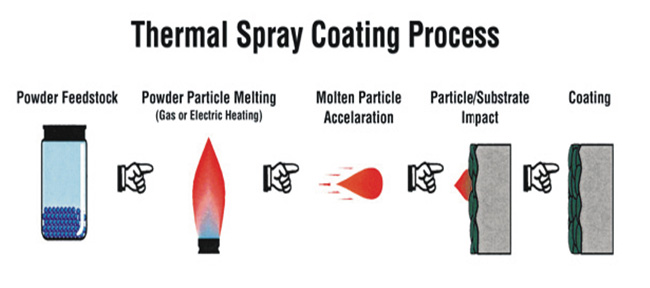

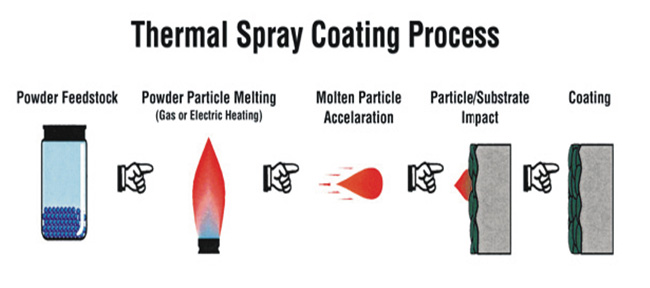

The coating technology undertaken by us is Thermal Spraying which is a cold process hence there is no mechanical or metallurgical distortions in the component. (At point of contact temperature is below 100 degrees centigrade).

Applying High Performance Plasma coatings enables the surface of engineering components to improve their performance, reduce cost by using cheaper base materials, extend working life two to five times depending upon the application in terms of wear & corrosion resistance ultimately enhances the reliability.

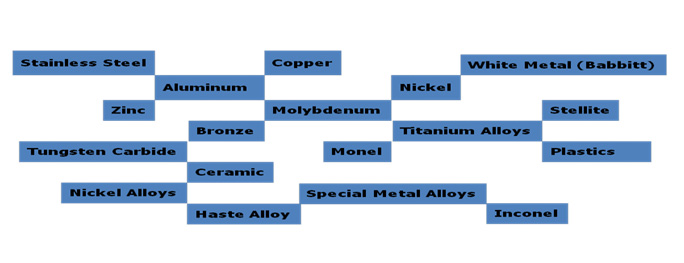

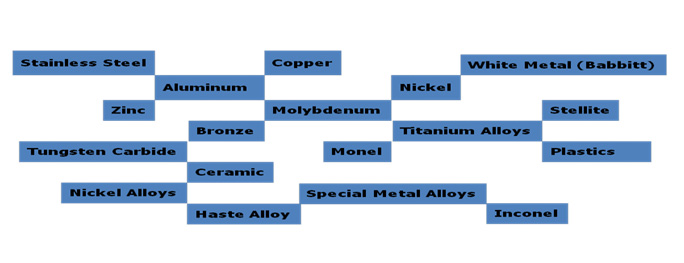

Materials used in Thermal Spraying

Send Enquiry

Send Enquiry

We also carry out precise Machining and Grinding work at site on Heavy jobs, which cannot remove from the machine.

We have well trained and qualified team of Technician for doing the job at work site. They already had done the challenging and critical job at work site and our client’s are satisfy with our quality and best services for work given to us.

THERMAL SPRAY APPLICATIONS IN VARIOUS INDUSTRIES

Given below are the industry-wise details of components which are subject to surface damage. VI has undertaken coating jobs on most components in Paper, Printing, Chemical, Steel, Hydro, and Steam & Thermal Power Sectors.

Chemical & Fertilizer,

Oil & Gas,

Steel,

Pulp & Paper,

Marine,

Auto Mobile,

Heavy Engineering,

Textile,

Printing & Packaging,

Power Generation,

Aviation,

Pump Sleeve,

Reciprocating Plunger,

Ball Valves,

Feed Screw,

Mixers,

Vessels,

Chemical storage tank,

Gate Valve,

Mechanical Seal,

Pump casing,

Pump Housing,

Impeller,

Cross Head,

Pulverizer,

Flap Valve,

Compressor Rod,

Boiler Tube,

Crank shaft,

Rotor shaft & cover

PAPER

Yankee/M. G Cylinders, Dryer Cylinder, Re-winder Rolls, Calendar Rolls, Pope Reel, Cooling Cylinder, Coated Pump Sleeves, Felt Guide Rolls, Separator Rolls, Winder / Reeling Drum, Press Rolls, and Bearing Journal Reclamation.

Printing

Gripper fingers and pads, Chill rolls, In feed rolls, Ink fountain rollers , Water pan rollers, Copper vibrator rollers, Metering rollers, Glue rolls, Folder cylinders, Bearing cells, Former boards and noses, Angle bars, Vibrator gudgeons, Cutting irons.

Chemical

Mixers, Vessels, Storage Tanks, Centrifuges, Pump Casings, Reciprocating Plungers, Pump Sleeves, Ball Valves, Mechanical Seals, Drive Shafts, Feed Screws, Compressor Rods.

Steel

Stabilizer Rolls, Hearth Rolls, ACBR ( Anti Cross Break Rolls), Bridle Rolls, Deflector Rolls, Sync Rolls, Pinch Rolls, Table Roller, Roll Chuck, Mud gun Nozzle, Cheek Plates, Screw Feeder Shafts, End Seal Plates, Mandrels, Shafts, Sleeves and bushes for support rolls.

Hydro Power

Runners, Cheek Plates, Guide vane bushes, Guide vanes, Labyrinth seals, Guide vane sleeves, Inlet gates, Radial gates, Shaft gates, Draft tube gates.

Steam Turbine

Inner surfaces of turbine housings, Horizontal joints of turbines, Vertical sealing surfaces of housings and guide vanes/ carriers, Steam steering parts ,Turbine related steam pipes ,Steam valves and parts, Bearing and sealing faces of rotor shafts, Babbitt bearings.

| Sr. No. |

Hard Chrome Plating |

Thermal Spraying |

| 1 |

Limited wear resistant properties

This process has moderate wear resistant properties hence component gets worn-out in short span of time. |

Extremely good wear resistant properties.

This process imparts very good wear resistant properties and the coating last for more than 2 / 3 times than HCP. This is due to high hardness characteristic of the coating and component life increase 2 to 3 times. |

| 2 |

Limitation of component size.

The component size is limited to the size of the coating bath; hence components of bigger dimensions cannot be coated. |

No Limitation on the size of the component.

Components of any shape, size and dimensions can be coated by this process. |

| 3 |

Material limitations in Plating

Chrome, Nickel, Zinc and Copper can only be used for coating. Alloys cannot be used for plating. |

Wide range of coating materials.

A wide range of metal and metal alloys are available as coating material in this process. (Ceramic, Carbide, Nitride, Stallite, Aluminum, Molybdenum, Zinc, Monel, Haste alloy, Nickel.) Alloys will provide necessary resistant properties to combats multiple wear mechanisms. |

| 4 |

In-situ operation not possible

The process is undertaken in a chemical bath which is not portable hence on site / in-situ plating not possible. |

An efficient In-situ coating is possible.

Coating equipments are compact and portable hence in-situ coating operation is possible. This saves substantial transportation time and cost, and also enables coating on wide range of components which can not be dismantled from machinery. |

| 5. |

Limitation on plating thickness.

Regular plating is done up to 200 – 300 microns and thicker plating results in de-bonding and chip-out. This is because there is no mechanical bonding in HCP process. |

Thicker coating is possible

5000 microns coating thickness is possible in Ferrous & Non-ferrous metal coatings.

350 – 400 microns coating thickness is possible in Carbide and Ceramic coatings |

| 6 |

Weak Corrosion resistant property

In this process micro cracks are present in the microstructure which allows corrosive elements to penetrate and reach the base metal. |

Extremely good Corrosion resistant property.

This process has a continuous surface and there are no micro cracks in micro structure, hence corrosive can not penetrate the coating and component remains free from corrosion for a very long time. |

| 7 |

Average Hardness in the plating.

HCP gives hardness up to 890 Hv maximum. |

Comparative High Hardness

1240 Hv hardness can achieved in Thermal Spray process. |

| 8 |

Health and Environment pollution.

Developed countries have banned the deployment of this process because of health hazard and highly polluted chemical discharge. |

Negligible Pollution Hazard.

Thermal Spray process has negligible health and pollution hazard. |

We can do accurately reclamation / metallization on any type & any size of component at site. After metalizing we can maintain very close dimensional tolerances as per job requirement. We request you to kindly let us know your specific requirements and advice us how best we can serve you. We highly appreciate your query or requirement for above cited subject.

In the meantime thanking you & looking forward to your kind response in this matter.

Send Enquiry

Send Enquiry

Send Enquiry

Send Enquiry

Send Enquiry